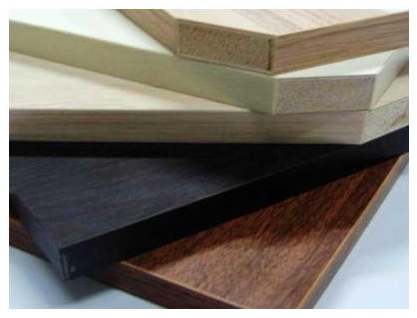

Amabhodi abhekene ne-melamine enziwe nge-particle board,I-MDF, ibhodi le-block kanye ne-plywood ehlanganiswe ndawonye nendawo.Ama-surface veneers ikakhulukazi asekhaya kanye ne-melamine evela kwamanye amazwe.Ngenxa yokumelana nomlilo, ukumelana nokugqokwa, kanye nokwelashwa kokucwiliswa emanzini, umphumela wokusetshenziswa ufana nowe-composite wood flooring.

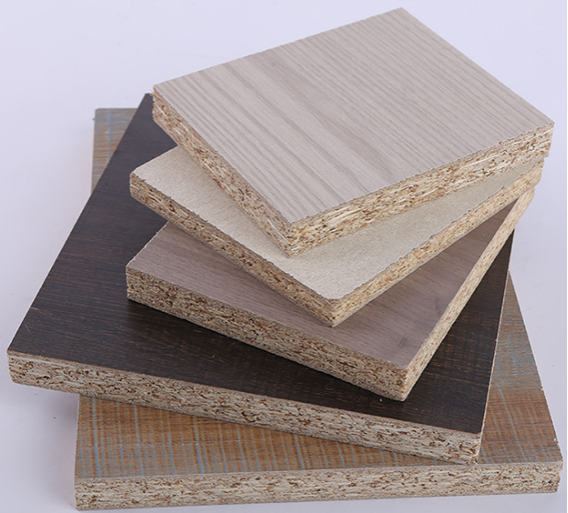

Ibhodi le-Melamine okuyibhodi lokwenziwa eline-melamine efakwe ifilimu enamathelayo yephepha le-veneer.Ibhodi lokuhlobisa elenziwe ngokucwiliswa kwephepha elinemibala ehlukene noma ukwakheka kokunamathelayo kweresin ye-melamine, yomiswe ngezinga elithile lokuphulukiswa, futhi ibekwe phezu kwebhodi lezinhlayiyana, i-medium density fiberboard, plywood, blockboard, multi-layer board. , noma enye i-fiberboard eqinile, ngemva kokucindezela okushisayo.Enqubweni yokukhiqiza, kuvame ukwakhiwa ngezingqimba eziningana zephepha, futhi ubuningi buncike enjongweni.

Gcoba iphepha lokuhlobisa kwisisombululo se-melamine bese ulicindezela kulo ngokucindezela okushisayo.Ngakho-ke, ibhodi elivikela umswakama elisetshenziselwa ifenisha ngokuvamile libizwa ngokuthi i-melamine-proof board.I-Melamine formaldehyde resin iyisisombululo esinokuqukethwe okuphansi kakhulu kwe-formaldehyde, ehambisana nemvelo.Le ndlela yokuyinamathela ayibangeli nje ukungcola kwesibili, kodwa futhi inciphisa ukukhululwa kwe-substrate ngaphakathi.Le ndlela yokwelapha iye yaqashelwa abantu abaningi futhi ngokuvamile yenziwa ngale ndlela.

Inqubo evame ukusetshenziswa yokucubungula ye-melamine veneers iyinqubo yokucindezela okushisayo.Kodwa-ke, kufanele kuqashelwe ukuthi ngesikhathi sokwelashwa kokucindezela okushisayo, kunezici ezintathu zokucubungula ezizothinta umphumela wawo wokugcina.Lezi zici ezintathu isikhathi sokucindezela okushisayo, izinga lokushisa lokucindezela okushisayo, kanye nokucindezela okufanele.

Izinto Ezintathu Zenqubo Yokucindezela Okushisayo yeI-MelamineIphepha

Isikhathi sokucindezela esishisayo: Ubude bayo buncike esilinganisweni sokuphulukisa kanye nezinga lokushisa lokucindezela elishisayo le-melamine resin, ngokuvamile phakathi kwamasekhondi angu-40-50.Isikhathi eside singabangela ukuphulukiswa kwe-resin ngokweqile, ukulahlekelwa ukunwebeka, futhi kubangele kalula imifantu noma ingcindezi yangaphakathi emkhiqizweni, okuholela ekuqhekekeni nasekujikeni ngesikhathi sokucubungula okulandelayo.Uma isikhathi sisifushane kakhulu futhi ukuphulukiswa kwe-resin kunganele, kulula ukukhiqiza i-adhesive board phenomenon, futhi kuthinta imisebenzi yomzimba kanye namakhemikhali ebusweni bomkhiqizo, okuthinta ukuqina komkhiqizo.

Izinga lokushisa lokucindezela okushisayo:ikakhulukazi idlala indima ebalulekile ekuphenduleni kwamakhemikhali e-melamine resin, okungukuthi isheshisa ukuphulukiswa.Ngokwezidingo zangempela zokukhiqiza kanye nesipiliyoni sombhali, izinga lokushisa lepuleti elicindezelwe elishisayo lifaneleka kakhulu ku-145-165 ℃.Izinga lokushisa eliphezulu lisiza ngokudiliza ngemva kokucindezela, futhi linganciphisa isikhathi sokucindezela okushisayo futhi andise ukukhiqizwa.Kodwa-ke, izinga lokushisa elidlulele livimbela i-resin ukuthi ingagelezi futhi iqiniswe ngokufanayo, okuholela emazingeni amancane ebusweni bebhodi.

Aingcindezi efanele: Ingaqinisekisa inhlanganisela enhle phakathi kwe-substrate nephepha le-melamine.Ngaphansi kwesenzo sokushisa okufanele nokucindezela, inhlaka ephepheni le-melamine iyancibilika futhi iqine, yakhe indawo evalekile neminyene.Ingase futhi igcwalise ama-pores amancane angazinzile endaweni ye-substrate.Uma ingcindezi ngokuvamile i-2.0-3.0MPa, kunconywa ukusebenzisa ingcindezi ephansi ngangokunokwenzeka ngaphandle kokuthinta ikhwalithi yomkhiqizo, okuzuzisa impilo yesevisi yemishini, uwoyela we-hydraulic, kanye nesakhiwo sangaphakathi se-substrate.Kodwa ukucindezela okuphansi kakhulu kuthinta amandla okubopha kanye nekhono lokugeleza kwe-resin phakathi kwe-substrate nephepha le-melamine.

Ukwakhiwa:

I-Melamine “ingenye yezinto ezinamathelayo zenhlaka ezisetshenziselwa ukwakha lolu hlobo lwebhodi.Iphepha elinemibala ehlukene noma ukwakheka licwiliswa ku-resin, lomiswe ngezinga elithile lokuphulukiswa, bese libekwa phezu kwebhodi lezinhlayiyana, i-medium density fiberboard, block board kanye neplywood.Kuyibhodi lokuhlobisa elenziwe ngokucindezelwa okushisayo, futhi igama elijwayelekile i-melamine efakwe ifilimu enamathelayo yefilimu ye-adhesive board yokwenziwa, Ukubiza ibhodi layo le-melamine empeleni kuyingxenye yokwakheka kwayo kokuhlobisa.Ngokuvamile yakhiwe ngephepha elingaphezulu, iphepha lokuhlobisa, iphepha lokumboza, nephepha eliphansi.

I-1.) Iphepha elingaphezulu libekwe phezu koqweqwe olungaphezulu lwebhodi lokuhlobisa ukuze kuvikelwe iphepha lokuhlobisa, okwenza ubuso bebhodi bubonakale kakhulu ngemva kokushisa nokucindezela.Ingaphezulu lebhodi liqinile futhi aligugi, futhi lolu hlobo lwephepha ludinga ukusebenza kahle kokumuncwa kwamanzi, luhlanzekile futhi lumhlophe, futhi lubonisa ngale ngemva kokucwiliswa.

2.) Iphepha lokuhlobisa, elaziwa nangokuthi i-wood grain paper.Inombala oyisisekelo noma ongenawo umbala wesisekelo, futhi iphrintiwe emaphethini ahlukahlukene ephepha lokuhlobisa.Ibekwe ngaphansi kwephepha elingaphezulu, ikakhulukazi ngezinhloso zokuhlobisa.Lesi sendlalelo sidinga ukuthi iphepha libe namandla okusibekela amahle, ukumiliselwa, nokusebenza kokuphrinta.

3.)Iphepha lekhava, elibuye laziwe njengephepha elimhlophe le-titanium, ngokuvamile lifakwa ngaphansi kwephepha lokuhlobisa lapho kukhiqizwa amaphaneli okuhlobisa anombala okhanyayo ukuze kuvinjelwe ungqimba olungezansi lwe-phenolic resin ukuthi lungangeni phezulu.Umsebenzi wayo oyinhloko ukumboza amabala ombala endaweni engaphansi.Ngakho-ke, ukufakwa okuhle kuyadingeka.Lezi zinhlobo ezintathu zephepha ezingenhla zifakwe ne-melamine resin ngokulandelanayo.

4.)Iphepha lesendlalelo esiphansi liyisisekelo samabhodi okuhlobisa, adlala indima yomshini ebhodini.Icwiliswe ku-phenolic resin adhesive futhi yomisiwe.Ngesikhathi sokukhiqiza, izingqimba eziningana zinganqunywa ngokusekelwe enjongweni noma ukushuba kwebhodi lokuhlobisa.Uma ukhetha lolu hlobo lwefenisha yephaneli, ngaphezu kokwanelisa umbala nokuthungwa, ikhwalithi yokubukeka nayo ingahlukaniswa nezici eziningana.Kungakhathaliseki ukuthi kukhona amabala, imihuzuko, ama-indentations, izimbotshana, umbala ofanayo kanye nokucwebezela, noma ngabe kunamabhamuza, nokuthi kukhona izinyembezi zephepha zendawo noma amaphutha.

Mangaki amabhodi abhekene ne-melamine?

Ibhodi lezinhlayiyana ezibhekene ne-melamine

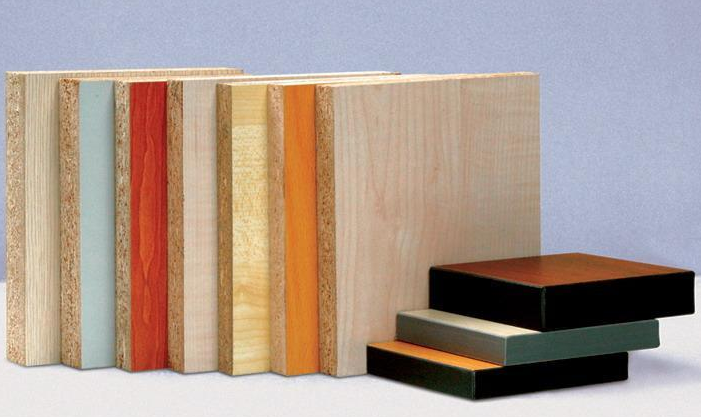

I-Melamine ibhekene ne-MDF

I-Melamine ibhekene ne-plywood

Ukusebenza kwebhodi lokuhlobisa i-melamine:

1. Ingakwazi ukulingisa ngokukhululekile amaphethini ahlukahlukene anemibala ekhanyayo, futhi isetshenziswe njengama-veneers amabhodi ahlukahlukene okwenziwa.Inokuqina okuphezulu, ukumelana nokugqoka, nokumelana nokushisa okuhle.

2. Inokumelana okujwayelekile namakhemikhali futhi ingamelana nokuhuzuka kwezincibilikizi ezivamile njengama-asidi, ama-alkali, uwoyela, notshwala.

3. Indawo ibushelelezi futhi kulula ukuyinakekela futhi ihlanzekile.Ibhodi le-Melamine linezakhiwo ezinhle kakhulu ezingenakuhlanganiswa nezinkuni zemvelo, ngakho-ke livame ukusetshenziswa ezakhiweni zasendlini kanye nomhlobiso wefenisha ehlukahlukene namakhabhinethi.

Ibhodi le-melamine liyimpahla yokuhlobisa odongeni.Imininingwane ejwayelekile: 2440mm × 1220mm, ukujiya 8mm -25mm.

Okuhle nokubi:

Izinzuzo zeebhekene ne-melamineibhodiyilezi: indawo eyisicaba, ukuwohloka okuncane ngenxa ye-coefficient efanayo yokunwetshwa ezinhlangothini zombili zebhodi, umbala ogqamile, indawo ekwazi ukumelana nokuguga, ukumelana nokugqwala, kanye nenani lezomnotho.

Ububi balolu hlobo lwebhodi ukuthi lijwayele ukuqhekeka emaphethelweni ngesikhathi sokuvalwa konqenqema, futhi lingavalwa kuphela liqonde ngaphandle kwemiphetho ebukhali.

Isikhathi sokuthumela: Aug-28-2023